- Treatment chamber with ultrasound predisposition

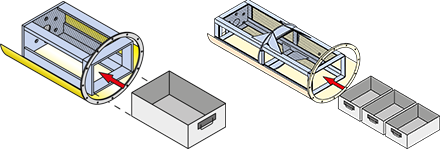

- Automatic loading door

- Rotating/rocking device with inverter

- Manual basket upper closure

- Nr. 2 solvent tanks

- Continous distillation system

- Vacuum pump

- Distiller pump for sludge recirculation and discharge

- Storage tank for waste oil (7,5 L)

- Water separator "hourglass"

- Welded and flanged hydraulic circuit

- 200 micron chips filter

- Fine filter bag

- Filters' drying

- Lateral streams under pressure

- SIEMENS S7-1200 computer + TP700 touch screen 7”

- Ethernet / Router for remote access

- Integrated electric heating

- Stainless steel components

- Fully closed fairings

- Solvent safety tray

- High efficiency ultrasounds with titanium transducers

- Electropolished treatment chamber

- Automatic basket upper closure

- Second fine filter (parallel to the first)

- Cartridge filter group

- Second distiller (stripping)

- Enlarged waste oil tank

- Plug&Play configuration

- Anti-rust oil spray application system

- Anti-rust oil immersion system

- Special fairings' colours

- Fix manual roller unit

- Automatic loading/unloading system (SC50)

- 12” Control panel

| Belademaße |

480 x 660 x 400 (480 x 960 x 200) |

| Belade- volumen |

120 |

| Beladegewicht |

150 |

| Kammer- volumen |

390 |

| Maschinenab-messungen |

3200 x 2400 x 2960 |